marks a new chapter in Penang’s transit journey, bringing efficient and reliable transportation closer to home. As work progresses, every step is geared towards creating a seamless and accessible network for all.

Key Construction Activities for the LRT Mutiara Line

Technical Information

Technical Information

- Land Viaduct Gateway

- Sea Crossing Bridge

- ET High Level Specification

- Station

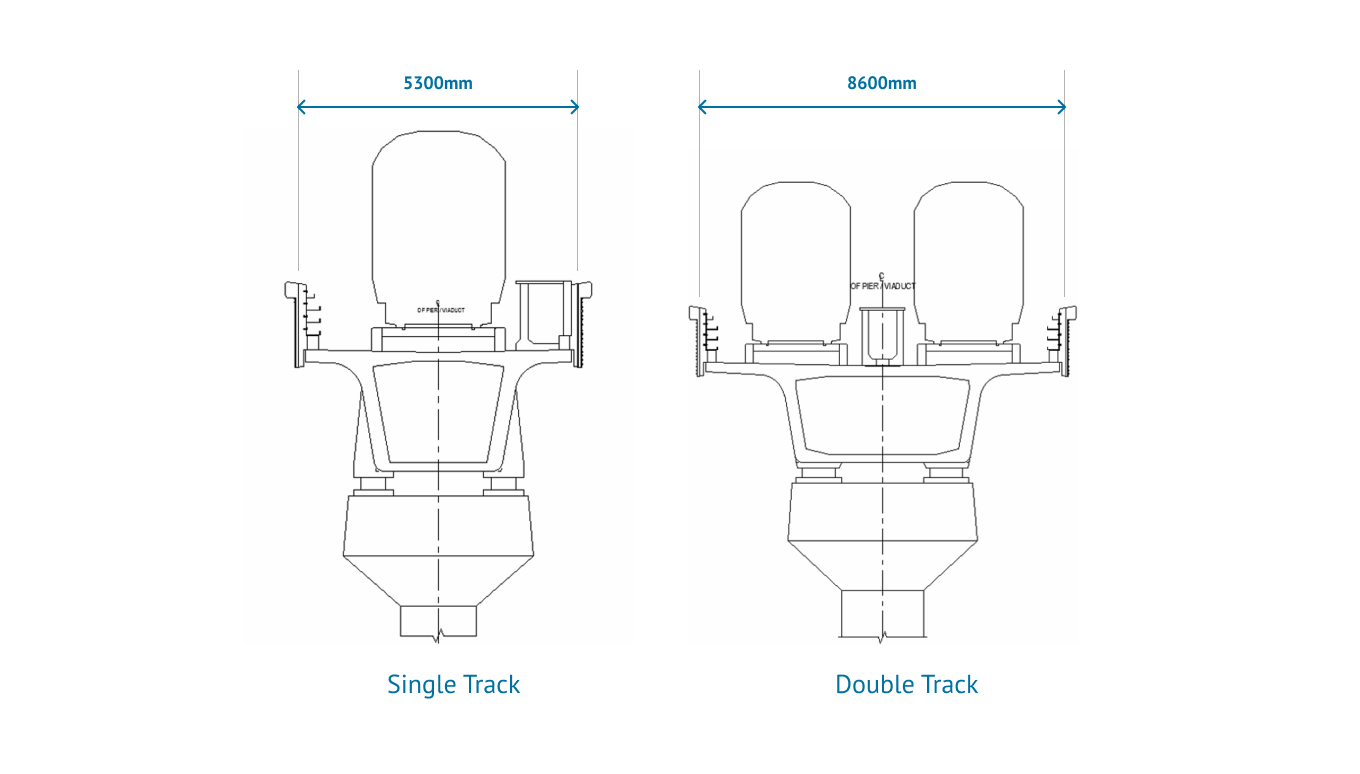

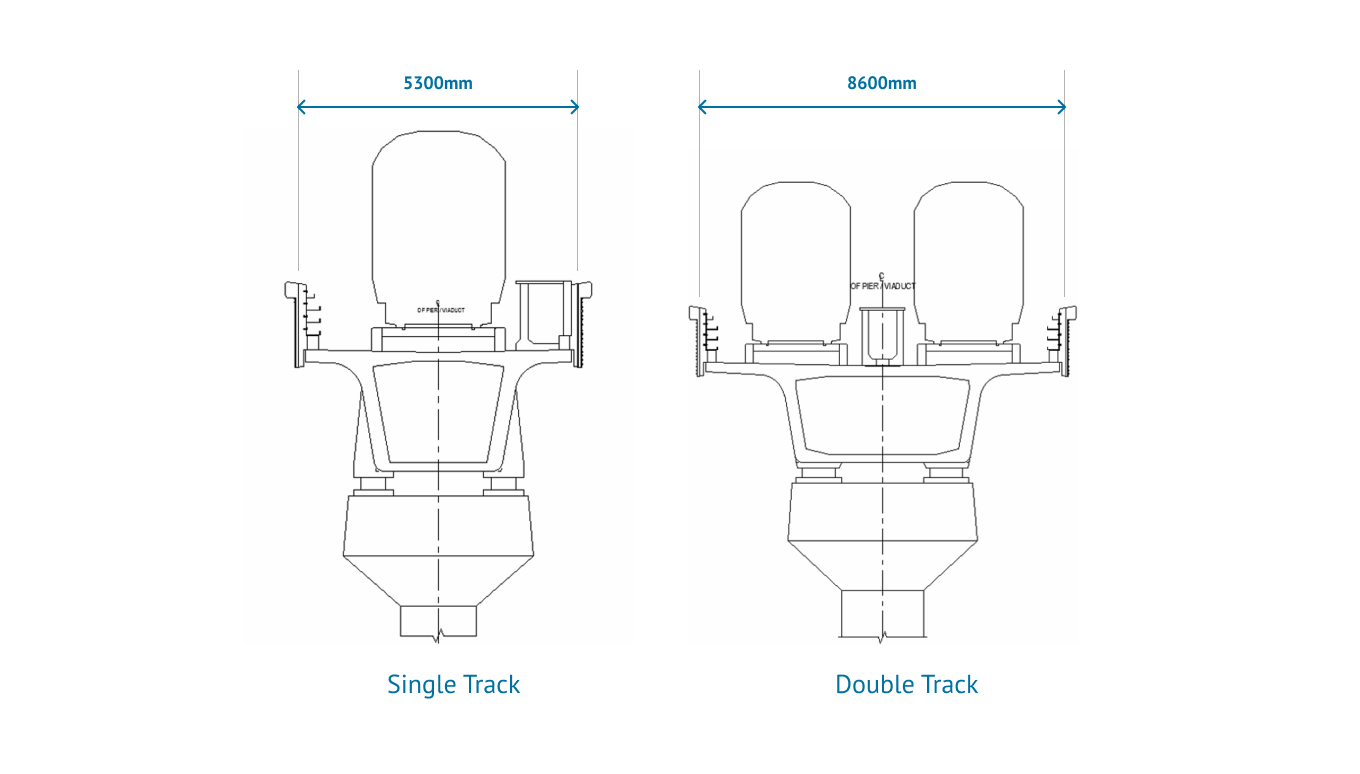

The typical cross section for single and double track segmental box girder viaduct as shown below.

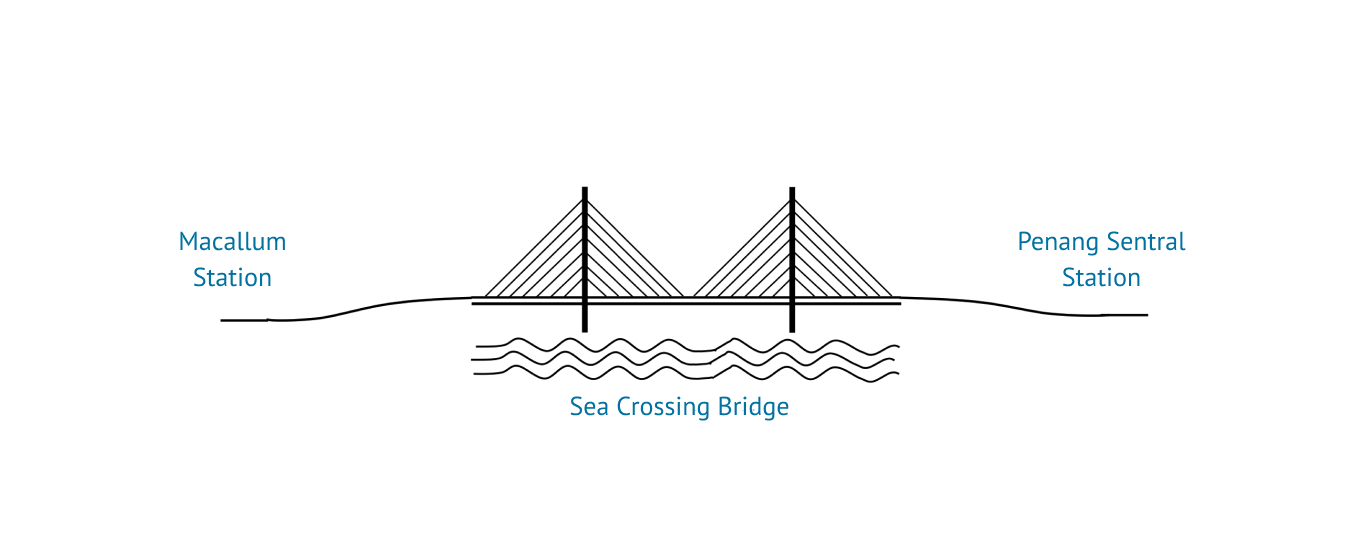

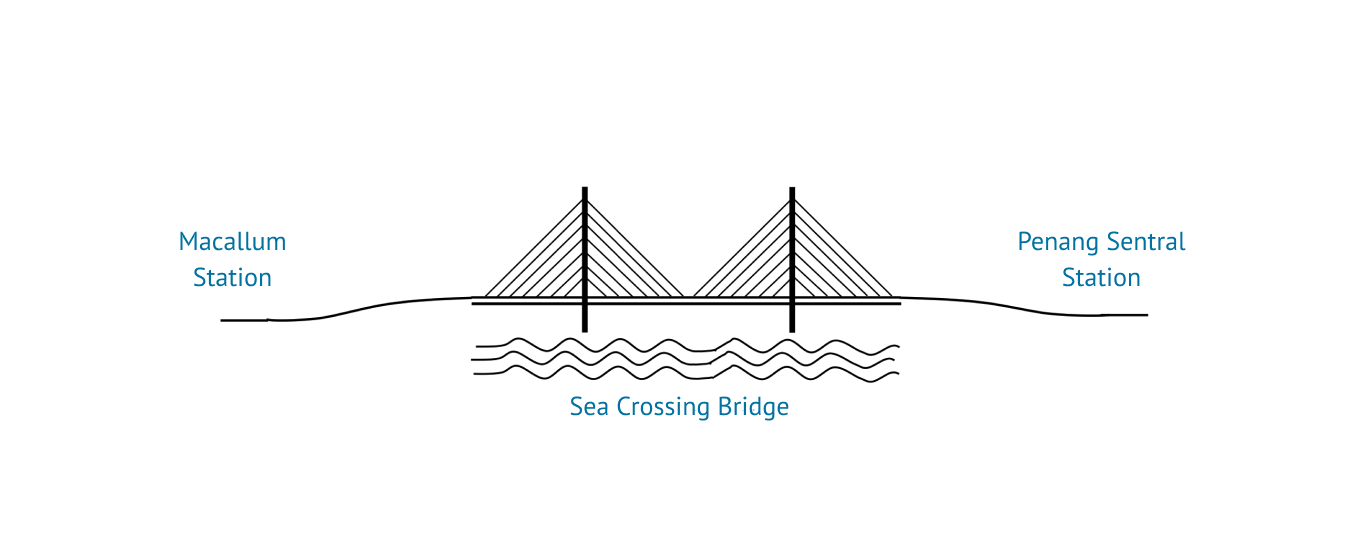

The LRT Mutiara Line introduces the northern region’s first sea-crossing bridge for trains, linking Macallum Station on the island to Penang Sentral on the mainland. Built with passenger safety in mind, the bridge includes an emergency walkway to ensure a safe exit in case of any unexpected situations.

Electric Train (ET) High Level Specification

Land Use Category

Day

Technology

Low to Medium Capacity LRT

Capacity

Minimum 405 Pax at AW3

Electrification

750V DC with option to propose full battery system

Max. Speed

70km/h (Operation), 80km/h (Design)

Alignment Flexibility

Turning Radius: 45m (Mainline), 40m (Depot)

Vertical Gradient: 6%, Hog & Sag: 800m

Material

Aluminium or Stainless Steel

Train Control

GoA4 with Attendant during initial operation years

Dimension

Length: <70m

Width: 2.65m

Height of ET: <3.8m

Floor-to-Track Height: <1.1m

Weight

Maximum Axle Load: 13T

Maximum Imposed Load: 234kN on 40m Guideway Span

Safety Features

Passenger Emergency Communication Unit (PECU)

Saloon and Exterior CCTV

Emergency lighting and Ventilation for 60 minutes

Fire Barriers of 30 minutes

Crashworthiness according to EN 15227

Alignment Capacity

2030–2040: 6,045

2041–2050: 9,040

2051–2060: 10,910

Journey Time (approximately)

PSR-A to KOMTAR: 45 minutes

PSR-A to Penang Sentral: 49 minutes

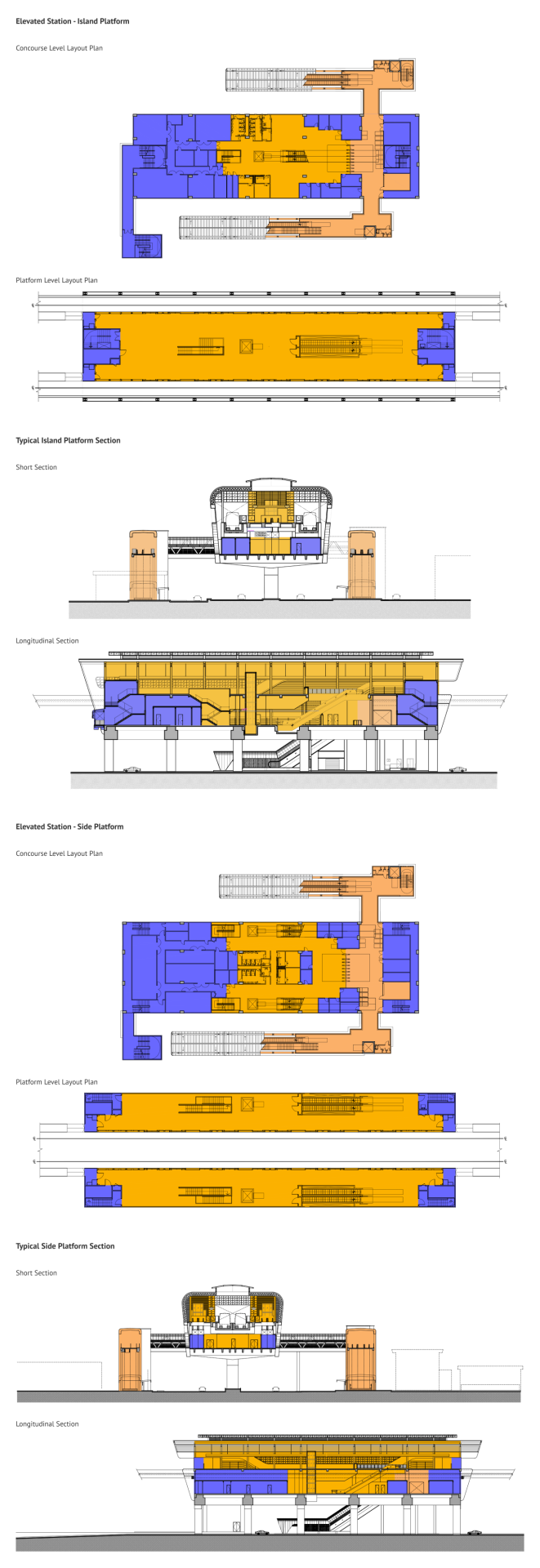

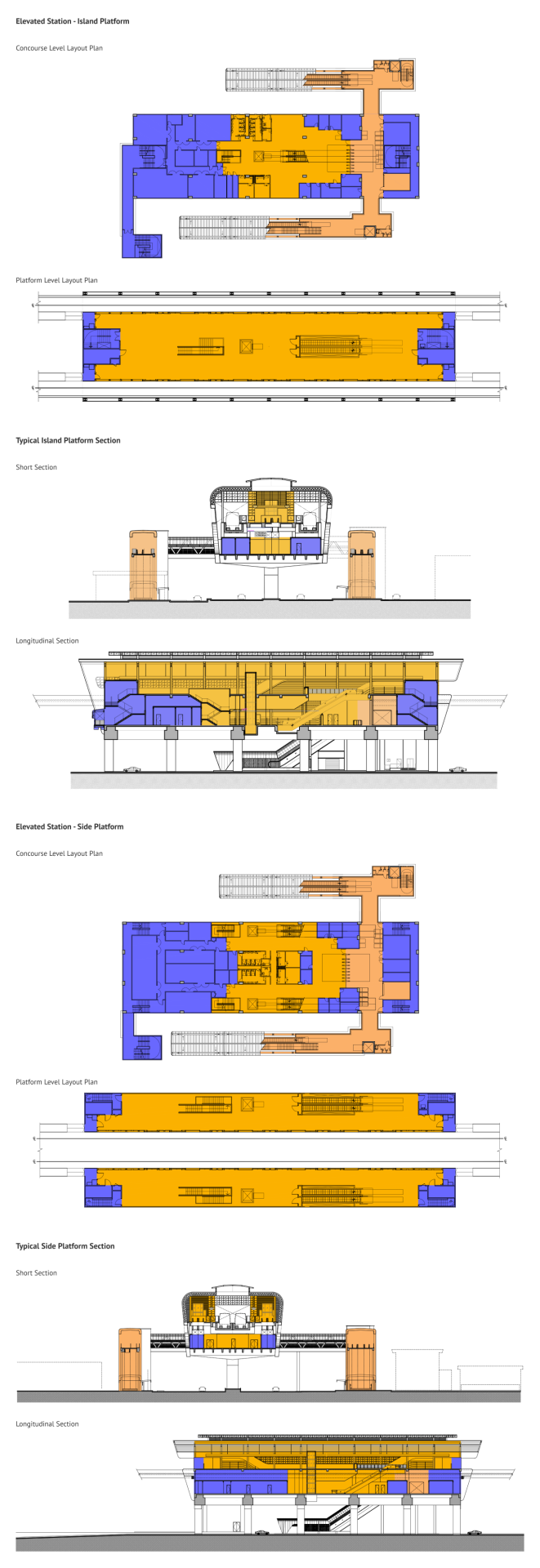

• All elevated stations are either side platform or island platform.

• All stations will be equipped with universal access facilities such as ramp access and tactile tiles.

• Other commuter facilities shall include car and bus laybys, Park & Ride at selected stations, toilet, surau and baby changing room inside the station.

Land Viaduct Guideway

The typical cross section for single and double track segmental box girder viaduct as shown below.

Sea Crossing Bridge

The LRT Mutiara Line introduces the northern region’s first sea-crossing bridge for trains, linking Macallum Station on the island to Penang Sentral on the mainland. Built with passenger safety in mind, the bridge includes an emergency walkway to ensure a safe exit in case of any unexpected situations.

ET High Level Specification

Electric Train (ET) High Level Specification

Land Use Category

Day

Technology

Low to Medium Capacity LRT

Capacity

Minimum 405 Pax at AW3

Electrification

750V DC with option to propose full battery system

Max. Speed

70km/h (Operation), 80km/h (Design)

Alignment Flexibility

Turning Radius: 45m (Mainline), 40m (Depot)

Vertical Gradient: 6%, Hog & Sag: 800m

Material

Aluminium or Stainless Steel

Train Control

GoA4 with Attendant during initial operation years

Dimension

Length: <70m

Width: 2.65m

Height of ET: <3.8m

Floor-to-Track Height: <1.1m

Weight

Maximum Axle Load: 13T

Maximum Imposed Load: 234kN on 40m Guideway Span

Safety Features

Passenger Emergency Communication Unit (PECU)

Saloon and Exterior CCTV

Emergency lighting and Ventilation for 60 minutes

Fire Barriers of 30 minutes

Crashworthiness according to EN 15227

Alignment Capacity

2030–2040: 6,045

2041–2050: 9,040

2051–2060: 10,910

Journey Time (approximately)

PSR-A to KOMTAR: 45 minutes

PSR-A to Penang Sentral: 49 minutes

Station

• All elevated stations are either side platform or island platform.

• All stations will be equipped with universal access facilities such as ramp access and tactile tiles.

• Other commuter facilities shall include car and bus laybys, Park & Ride at selected stations, toilet, surau and baby changing room inside the station.

Noise Level

| Land Use Category | L Aeq Day (7am - 10pm) | L Aeq Night (10pm - 7am) | L max Day & Night (10pm - 7am) |

|---|---|---|---|

| Noise Sensitive Areas, Low Density and Suburban Residential Areas | 60 dBA | 55 dBA | 75 dBA* |

| Urban Residential Areas | 65 dBA | 60 dBA | 80 dBA* |

| Commercial Business Zone | 70 dBA | 65 dBA | 80 dBA* |

| Industrial Zone | 75 dBA | 75 dBA | NA |

*Average train passby L max in 1 hour

Land Use Category

L Aeq

Day

7am-10pm

L Aeq

Night

10pm-7am

L Max

Day & Night

10pm-7am

Noise Sensitive Area,

Low Density and

Suburban Residential Areas

60 dBA

55 dBA

75 dBA*

Urban Residential Areas

65 dBA

60 dBA

80 dBA*

Commercial Business Zone

70 dBA

65 dBA

80 dBA*

Industrial Zone

75 dBA

75 dBA

NA

*Average train passby L max in 1 hour

Built for Safety

- Station Safety

- Train Safety

- Track Safety

- Fire Safety

CCTV & Real-Time Monitoring

Continuous surveillance and 24/7 monitoring by the Operation Control Centre (OCC) keep stations secure.

Police Patrol

Regular patrols ensure safety and security across all stations.

Help Points

Located at platforms, providing immediate two-way communication with the OCC in case of emergencies.

Automatic Platform Gates (APG)

Gates prevent access to the tracks until the train arrives, ensuring safe boarding.

Train Protection & Supervision

Automatic Train Protection (ATP) monitors speed and distance, while Automatic Train Supervision (ATS) ensures that trains move only when safety checks are complete.

Power Reliability

Backup systems on trains provide lighting, ventilation, and communication during emergencies.

Help Points

Available inside trains, connecting passengers directly with the OCC.

Comprehensive CCTV Coverage

Designed in compliance with EN 15227 standards, ensuring enhanced structural safety during collisions.

Fire Safety Standards

Trains are designed with a 30-minute fire barrier and utilize non-combustible, non-dripping, and low energy release-rate inflammable materials to mitigate fire risks.

Train Crashworthiness

Designed in compliance with EN 15227 standards, ensuring enhanced structural safety during collisions.

Emergency Walkway

Provides a safe evacuation route to the nearest station during emergencies.

Fail-Safe Systems

Redundancies are built into critical track equipment, ensuring safety and continuous operation even in case of failure.

Condition Monitoring

Continuous checks ensure tracks and equipment remain safe and operational at all times.

Safe Materials

Our trains use low smoke, halogen-free, non-combustible materials to enhance passenger safety.

Fire-Resistant Interiors

Non-splintering, fire-resistant materials ensure a safer environment inside each carriage.

Advanced Detection

Equipped with fire and smoke detection systems, trains alert the Operation Control Centre automatically in emergencies.

Emergency Equipment

Each carriage is fitted with at least two fire extinguishers for quick access during an incident.

Station Safety

CCTV & Real-Time Monitoring

Continuous surveillance and 24/7 monitoring by the Operation Control Centre (OCC) keep stations secure.

Police Patrol

Regular patrols ensure safety and security across all stations.

Help Points

Located at platforms, providing immediate two-way communication with the OCC in case of emergencies.

Automatic Platform Gates (APG)

Gates prevent access to the tracks until the train arrives, ensuring safe boarding.

Train Safety

Train Protection & Supervision

Automatic Train Protection (ATP) monitors speed and distance, while Automatic Train Supervision (ATS) ensures that trains move only when safety checks are complete.

Power Reliability

Backup systems on trains provide lighting, ventilation, and communication during emergencies.

Help Points

Available inside trains, connecting passengers directly with the OCC.

Comprehensive CCTV Coverage

Designed in compliance with EN 15227 standards, ensuring enhanced structural safety during collisions.

Fire Safety Standards

Trains are designed with a 30-minute fire barrier and utilize non-combustible, non-dripping, and low energy release-rate inflammable materials to mitigate fire risks.

Train Crashworthiness

Designed in compliance with EN 15227 standards, ensuring enhanced structural safety during collisions.

Track Safety

Emergency Walkway

Provides a safe evacuation route to the nearest station during emergencies.

Fail-Safe Systems

Redundancies are built into critical track equipment, ensuring safety and continuous operation even in case of failure.

Condition Monitoring

Continuous checks ensure tracks and equipment remain safe and operational at all times.

Fire Safety

Safe Materials

Our trains use low smoke, halogen-free, non-combustible materials to enhance passenger safety.

Fire-Resistant Interiors

Non-splintering, fire-resistant materials ensure a safer environment inside each carriage.

Advanced Detection

Equipped with fire and smoke detection systems, trains alert the Operation Control Centre automatically in emergencies.

Emergency Equipment

Each carriage is fitted with at least two fire extinguishers for quick access during an incident.